Today the word “Chronometer” is associated almost exclusively with Swiss timepieces. The COSC (Contrôle Officiel Suisse des Chronomètres) has managed to monopolize the word (among other things) but many may not know that the standards were actually formalized by Webster C. Ball in America in the 1890s. Nearly 80 years before COSC and about 30 years before the Société Suisse de Chronométrie the specifications for a chronometer were set up in America. They were changed very little and rebranded the Swiss standard. This re-appropriation glosses over the tragic history that led to the regulations that have defined the chronometer for nearly a century.

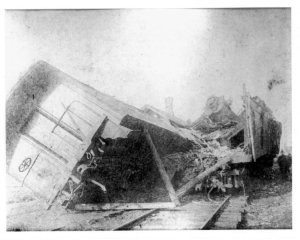

All too often great change comes about through tragedy. Chronometry is unfortunately in this category. In 1891, mail train #14 collided with the Toledo Express at Kipton Station in Ohio. The impact occurred close to where the Toledo Express would normally have pulled on to a side-track to allow the passage of the much smaller and faster mail train. Nine men were killed in the accident. The believed cause was a pocket watch that was four minutes slow.

(Image taken from: http://postalmuseumblog.si.edu/2013/04/the-great-kipton-train-wreck.html)

In reaction to this incident, Webster Ball, an Ohio jeweler was assigned to investigate and this led to the Railroad Chronometer Standards of 1893.

The standards were as follows:

(copied from: http://www.appalachianhistory.net/2009/01/making-trains-run-on-time.html)

- Only American-Made watches may be used

- Open-faced dials with the stem at 12 o’clock

- Minimum of 17 functional jewels

- Maximum variation of 30 seconds per weekly check (+/-4 sec/day)

- Adjusted to at least 5 positions

- Adjusted for heat and cold and isochronism

- Indications with large bold Arabic numerals, outer minute division, second dial, heavy hands

- Breguet overcoil

- Micrometer adjustment regulator

- Double roller

- Steel escape wheel

- Anti-magnetic protection

- Jim-proof

- Lever set (this is a pain, but ensures the stem can’t be left out or the time accidentally changed)

While the Swiss clearly removed some of the above requirements, many are strikingly similar to today’s standards. Very shortly after these standards were published, almost every American watch manufacturer complied. This time period produced some of the most accurate (and beautiful) movements in American horology. One of the most popular ones used was the E.Howard Series 11. After a long time of searching, I pulled the trigger and found one I wanted to service.

One thing that is particularly important with these older pocket watches is to check the condition of the lettering on the plates (and the paint still in them.) If the letters are fully intact it is generally a sign that the watch has not been over-serviced, poorly serviced, or mechanically cleaned (modern methods tend to remove this detail.) Secondly, I made sure the dial had no hairline cracks. Howard watches tend to suffer badly from these as the dial is snapped on rather than screwed in place. This means that the process of removing the dial is a very delicate one requiring care and patience. Railroad dials also tend to suffer from wear because of the lever set mechanism. This mechanism requires that the glass be removed and a lever pulled up to set the time. In doing so, the dials were constantly exposed to the elements and as a result finding mint ones are tough.

This watch was about as close to perfect as I wanted. When it arrived I put it on the timing machine and found it was running over 2 minutes fast per day so I set about servicing it. After full disassembly I noticed some features that make these watches what they are. Every bridge, plate, and cock is stamped with the serial number to preserve and verify the originality of the piece. Fortunately all of these matched. Another rarely seen feature these have are adjustable banking pins. Without getting technical this is an interesting feature that allows for fine-tuning of the escapement.

After a very meticulous hand cleaning, reassembly, oiling, and regulating, this legendary piece is running as it should. The shape of this watch after nearly 100 years is insane. This is a watch that was cared for and will last another 100 years in good hands. It is a stunning example from the Golden Age of American horology that represents a forgotten tragedy and the birth of the world standards for chronometry.